Beam Alignment Substrate for Easier RHEED Beam Adjustment

Have you ever heard of a “beam alignment substrate”? These substrates are an efficient and easy way to both properly align and focus your RHEED electron beam and offer the ability to identify RHEED beam locations on your wafer for spatially resolved RHEED analysis. Beam alignment substrates supplied by kSA consist of a high-quality Si wafer coated with P43 phosphor; the same phosphor used to coat most UHV compatible RHEED screens. When the RHEED beam impinges on the alignment substrate, the phosphor fluoresces where the beam hits the substrate, allowing you to see the full profile of the electron beam on your sample.

Darryl Barlett, CEO of k-Space said, “The beam alignment substrates are easy to use and instantly let you know what’s going on with your electron beam: Where is it hitting the sample? How large an area am I sampling for the RHEED pattern? How much does the beam move on the sample when I adjust the x or y deflection? These are great things to know, and easily determined using the beam alignment substrate.”

k-Space supplies these P43 phosphor-coated silicon wafers in 1”, 2”, 3”, and 4” diameters to fit your chamber needs. Watch this video to learn more about how this small product can make a big impact when it comes to the effectiveness of your RHEED analysis.

Improve Defect Detection With kSA Emissometer’s New UV PL Feature

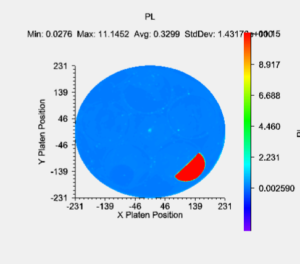

k-Space is proud to announce that the kSA Emissometer ex situ metrology tool for MOCVD wafer characterization now has ultraviolet photoluminescence capabilities for wafer carrier evaluation.

k-Space is proud to announce that the kSA Emissometer ex situ metrology tool for MOCVD wafer characterization now has ultraviolet photoluminescence capabilities for wafer carrier evaluation.

This allows wafer carrier manufacturers, reactor manufacturers, and epi houses to further evaluate their wafer carriers before use and throughout their lifecycle. This system uses a 365 nm LED focused at the wafer carrier and a filtered photodetector focused at the excitation point. The filter cuts off light for wavelengths shorter than 409 nm. This results in the ability to evaluate contamination on the wafer carrier.

The kSA Emissometer is used for determination of the quality of the carrier bake after the deposition run, quantitative determination of real surface emissivity for temperature set-point adjustments, and microcrack detection. The kSA Emissometer also provides statistical analysis of each individual pocket and web for carrier quality evaluation.

For additional information on the UV photoluminescence feature and the product specifications, please visit the kSA Emissometer page on our website.

k-Space Welcomes New Product Engineering Manager

k-Space is excited to announce that Craig Lennon has joined the team as a Product Engineering Manager. Craig is responsible for the technical oversight and development of our production-based in-line metrology tools. This includes custom metrology tools for the solar, glass, and automotive industries.

k-Space is excited to announce that Craig Lennon has joined the team as a Product Engineering Manager. Craig is responsible for the technical oversight and development of our production-based in-line metrology tools. This includes custom metrology tools for the solar, glass, and automotive industries.

Craig has extensive experience in project and engineering management, working previously for Terumo Cardiovascular, Picometrix (Macom), Pemstar, and ADC/Spectracom.

Craig stated, “The potential for growth and the reputation of k-Space are what attracted me here. I look forward to using my engineering and management experience to help turn customer needs into effective product solutions.”

With Craig in place the customer experience will be even more seamless. As always, k-Space takes pride in giving our customers excellent service, from initial contact through installation and technical support.

Free Gift With Submission to the RHEED Image Library

Are you a kSA 400 user? If so, we would like your help in adding content to our RHEED image and movie database, for the benefit of all kSA 400 users. The goal of this update is to expand the material systems represented in our existing RHEED Image Library (RIL) and to improve the content by providing even more movies and systematic RHEED image studies with full descriptions. Seeing these images and performing analysis on them is an effective way to broaden your knowledge of RHEED. The RIL is also a great way to share your research with others by using our network of 1,200 kSA 400 systems.

Are you a kSA 400 user? If so, we would like your help in adding content to our RHEED image and movie database, for the benefit of all kSA 400 users. The goal of this update is to expand the material systems represented in our existing RHEED Image Library (RIL) and to improve the content by providing even more movies and systematic RHEED image studies with full descriptions. Seeing these images and performing analysis on them is an effective way to broaden your knowledge of RHEED. The RIL is also a great way to share your research with others by using our network of 1,200 kSA 400 systems.

We hope you will help us expand the RIL (even if your employer’s policies do not allow you to accept a gift). We’ll take as many or as few images or movies as you’re willing to give us!

We expect to have the next version of the RHEED image library available to kSA 400 users by December 2019. We hope that you will take the time to contribute some of your images and movies to the library.

This contest has now concluded.

Come Visit Us at These Upcoming Events!

35th North American Molecular Beam Epitaxy Conference (NAMBE 2019) – September 22-25, 2019 – Ketchum, Idaho

German MBE 2019 – October 7-8, 2019 – Wuerzburg, Germany

66th International Symposium and Exhibition of the American Vacuum Society (AVS 66) – October 20-25, 2019 – Columbus, OH

SEMICON Japan 2019 – December 11-13, 2019 – Tokyo, Japan

For more events, visit k-space.com.