Analyze and control your Pulsed Laser Deposition (PLD) while deposition is taking place with in situ monitoring tools. Tools to measure your deposition rate, surface texture, and material stoichiometry while material deposition is occurring.

Pulsed Laser Deposition (PLD) is another physical vapor deposition (PVD) technique that utilizes a high-power pulsed laser beam focused on a source target inside a vacuum chamber. The material vaporized via the high power laser beam subsequently deposits as a thin film on a substrate which is facing the target (such as a silicon wafer). This process can occur in ultra-high vacuum or in the presence of a background gas, such as oxygen, commonly used when depositing oxide materials.

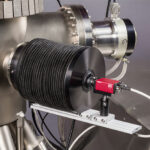

RHEED (Reflective High Energy Electron Diffraction) hardware from Staib and R-DEC can be used under higher pressure sputtering conditions that allow for shorter electron beam paths to avoid gas collisions. Being able to analyze the surface structure and morphology via electron diffraction on a phosphor RHEED screen via the kSA 400 RHEED system provides real-time film growth information. Growth rate, surface structure and texture, and lattice spacing/strain are easily determined using the kSA 400 system.

Standard sputtering systems currently being offered from PVD Products and AJA International provide these valuable in situ monitoring tools from k-Space as a standard option and are integrated into the deposition control software.